The Legend

Tracing the origins of the legendary 233 Formula hull to miami in the 1960s, the Edencraft Legend includes over sixty years of heritage that has made the company an irreplaceable part of Australian fishing folklore.

-

The Original Hull

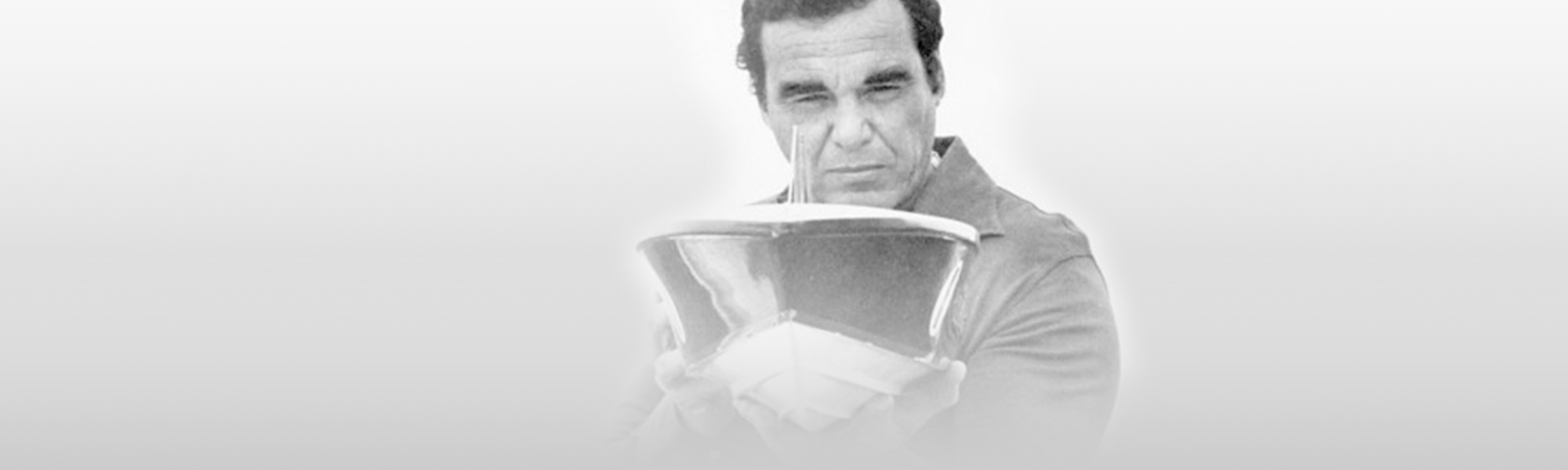

Early 1960s

Don Aronow, an American powerboat enthusiast, builds the original Formula 233 hull. With a need for speed, Don’s ‘formula for success’ is to assemble the best designers, boat builders and riggers in the industry, hence the ‘Formula’ name is born.

The first boat is a 233 Formula called Cigarette and it’s a winner. The boat revolutionises the industry and launches a new wave of boating ventures.

-

Bringing it home

The 233 Formula is brought to Australia by John Haines Snr., and built out of a factory in Goodna QLD.

The Formula finds its way to the recreational market, and are built for powerboat racing and day cruising. Hulls sell for as little as $4400, weigh just over a tonne with a 60 gallon tank, and hits a top speed of 72km/h with 220HP.

-

Yaltacraft

The 233 Formula hull mould is passed on to Yaltacraft.

-

Passing of Don Aronow

Don Aronow is murdered in Miami.

Due to the speed of the Formula’s, Don had been leading a double life supplying them to drug-running cartels and the US Government… at the same time!

Some say that this was uncovered by the drug cartels with tragic consequences for Don. Others say that his murder was at the hands of a rival boat builder jealous of his success.

-

Snapped up by Edencraft

Yaltacraft shut their factory doors and the Formula mould is snapped up by Edencraft, which

was a marine service centre in NSW at the time.“A Formula mould was sitting out the front of the factory, but the Yaltacraft bloke said it was sold and waiting to be collected. I told them the deal was off unless the Formula hull was included.

After some argy-bargy, we got it!” Edencraft introduces the 6m Offshore & 565 to its fleet and they quickly establish a best-in-class reputation.

-

Built by Edencraft

1990s – 2015

The moulds change hands and Edencraft’s are built in a number of different locations including Bairnsdale (Paul Bazinoz), Corowa (Harry Twikler), Gold Coast (Warren Lyons) & Geelong (Alan Ball).

Edencraft make a number of changes to the Formula’s over this time, including:

Wider gunwales, more spacious decks, more underfloor storage, one-piece helm, solid wave-breakers, pods, fibreglass stringer-systems, and foam filling.

-

Maher Family Purchase

Edencraft is purchased by the Maher Family Group in May 2016.

Owner Grant Maher had bought a 233 Formula from Edencraft’s previous owner and struck up a relationship. When the opportunity pops up to purchase the business Grant jumps at the opportunity.

Edencraft moves to a purpose built facility in Moolap, Geelong in December 2016. Significant works are undertaken to establish designated moulding, joining & fit-out sheds as well as administration offices.

-

New Branding

New Edencraft logo is designed incorporating the famous hull, traditional Edencraft insignia & modernised E badge.

-

Platinum Unveiled

Edencraft unveil the brand new 233 Formula Platinum model. With a redesigned deck, dash layout, larger fuel capacity & taller cabin, the legendary 233 Formula is given a modern style.

The 233 Formula Classic deck is also redesigned, taking out imperfections in the original mould, improving the dash layout to fit dual 16inch screens, and introducing an internal flange to hide bolts.

A new hardtop for the 233 Formula Classic is introduced with larger windows and updated style.

-

Growth and Expansion

A redesigned 6.0m Offshore deck includes a larger dash, incorporates a dive door & removed imperfections from the original mould.

Edencraft Marine is established and a marine service centre and retail store is built on site in a purpose-built facility.

Season one of Edencraft TV airs nationally on Aurora to great reviews.

-

565 Relaunched

The new and improved 565 is launched to a resounding welcome.

Significant updates include removing the planing plank for improved handling in messy seas, a flared bow, updated dash to fit a 16 inch screen, a swinging and removable dive door and widened side combings.

The 565 becomes Edencraft for ‘do anything, go anywhere’.

-

Mandurah Outboards Dealership

Edencraft extend their presence, with Mandurah Outboards becoming the exclusive Edencraft Dealer for Western Australia.

In-person enquiry support and after sales service is now available on the east and west coasts.

-

Australian Marine Centre and 5 Axis CNC

Australian Marine Centre become the exclusive Edencraft Dealer for Queensland.

The CMS 5 Axis CNC machining centre is established, promising rapid design development for the 255 and future models.

Learn more

Enter your details to receive the latest news from Edencraft